Feb 16 2024.

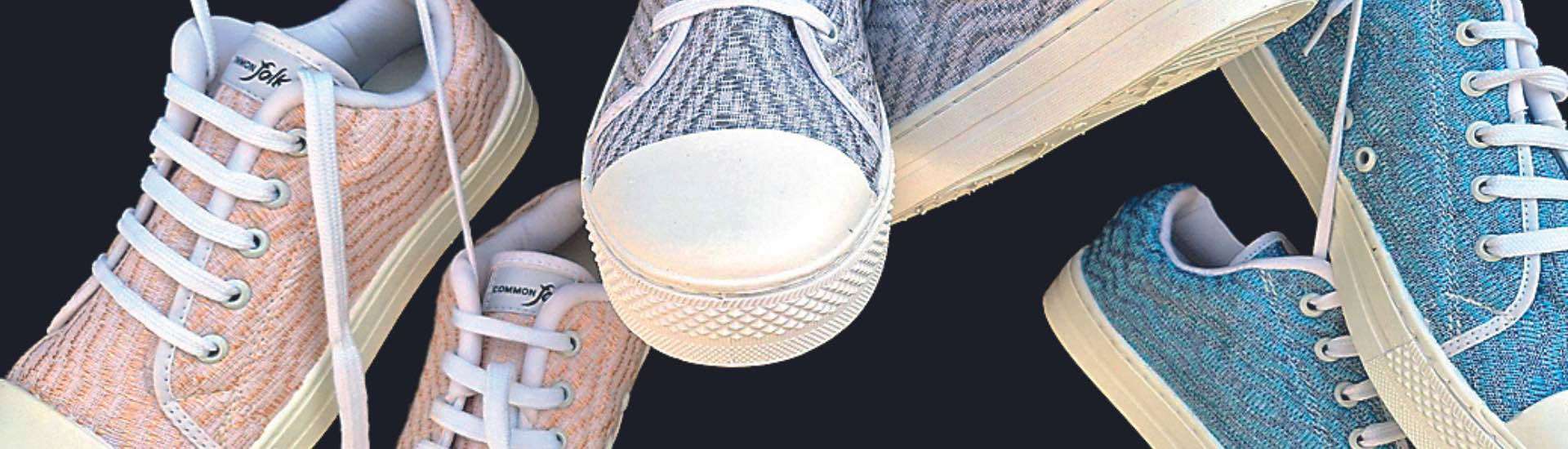

views 338Handloom textile weaving in Sri Lanka is said to date back to the 6th century BC as early as when Prince Vijaya from India landed in Sri Lanka and first saw Kuveni, a queen of an indigenous race of Yakshas (demon tribe) spinning yarn at the wheel. Fast forward to the 21st century, the traditional art and craft is still alive, surviving industrialization, a brutal civil war and even the recent crisis. Teaming up and pursuing the art with innovation, is a lawyer and a designer Sharendra Peiris and Thamali Dharmawardena, co-founders of the handloom textile R&D and innovation brand “Common Folk”. Since its inception in 2017, their main focus (motto) has been directed towards “uplifting heritage crafts with technology.” They are the creators behind unique sneakers designed with handloom. The art of handloom weaving involves the creation of textiles by interlacing threads primarily made out of cotton (coloured with natural dyes), on a loom operated manually.

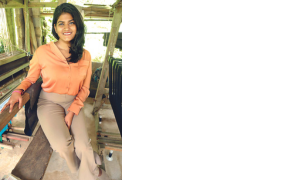

Pictured: Thamali Dharmawarden

After almost 5 years of research, Common Folk creates a breakthrough in the industry by discovering a production feasible method that adds waterproofing functionality and abrasive level durability to traditional handloom textiles. Sitting with Daily Mirror Life, Dharmawardena gives us an insight into their story and the evolution of their work. “Common Folk is a homage to all the brilliant people we have met and collecte dalong the way in the past 7-8 years. Firstly, Sharendra and I consider ourselves common folk. Throughout the years, we have learned and grown with the help of our talented artisans, tutors, technology partners, manufacturers, family, friends, and colleagues. No matter our differences, our passion for our respective crafts bind us. That passion and commitment make us all Common Folk."

Pictured: Sharendra Peiris

Q TELL US THE STORY OF HOW YOU GOT INTO HANDLOOM WEAVING? WHAT WAS THE INSPIRATION BEHIND PURSUING THIS TRADITIONAL CRAFT? Being very new to handloom weaving, it is actually less than ten years since we began pursuing it. The first exposure to the craft was during my second year in my BA programme. Our college took us to experience many different traditional crafts. But something about creating a textile from scratch and watching the weaving process in a handloom intrigued me the most. Being an analytical thinker, I then dove into researching handloom textiles and the handloom market. During this research, it became apparent to me that the Sri Lankan handloom market was on a decline. So our goal became to sustain and uplift it. We started out by wanting to make something new and unique that would open the handloom craft to much bigger opportunities. After years of R&D (almost 5 years), we finally found a method to add the waterproof functionality to handloom textiles. This was a breakthrough moment for us. But adding to our joy, we found out that our waterproof handloom textiles were very durable, making it feasible to be used in highly abrasive products. Being two people who love streetwear, Sharendra and I immediately went for sneakers!

Q CAN YOU WALK ME THROUGH THE PROCESS OF DESIGNING A PAIR OF SNEAKERS USING HANDLOOM TEXTILE? Initially, we start by selecting yarns and thread compatible with our waterproofing technology. We also select them in the colours and thicknesses we need. Our weavers then do their magic to warp the loom into our chosen design and begin weaving. One thing we didn’t want to compromise on was the natural sustainability and social sustainability factors of weaving handlooms. So once the designs are masterfully woven, we clean up the fabric and send it to be waterproofed by our locally based technology partners.This makes them extra durable too. Once done, we send them to our shoe manufacturing partners (locally based) to turn our fabric into sneakers. The entire process takes around 3-4 months. These shoes were the first product we launched for the retail market. We have fondly named them after some cities and places we hold dear. Are there any traditional techniques or tools that you incorporate into your weaving process? Are there any particular designs or patterns that you specialize in? One of our primary design innovations is the Ombre handloom, where the colours in the fabric are indistinguishable from one another, showing a smooth gradient effect. This technique is far smoother in transition than any other we have seen in the market.

Q YOU SURELY MIGHT HAVE HAD/HAVE SOME CHALLENGES OR DIFFICULTIES YOU HAVE TO OVERCOME PURSUING TRADITIONAL HANDLOOM? Yes definitely. We were relatively new to the handloom industry; we did not come from a family of handloom weavers or have ever experienced anything about handloom before. So our journey was not quick, short, or easy. But our purpose kept us going and helped us jump through all the obstacles we encountered. One other thing is our process in handloom right now is labour-intensive and very lengthy. We are combining three different industries and markets to create one product, and the most challenging part is coordinating with each of them to work smoothly. As we both have our day jobs, finding the time is a big challenge. Everything else in creating the product, missteps and side steps etc. we encounter are all part of the experience, and we don’t consider them to be difficulties or challenges. They are more of a motivator for us.

Q ASIDE HANDLOOM WOVEN SNEAKERS, WHAT ARE OTHER PRODUCTS DO YOU WORK WITH? Our main innovation is waterproof handloom fabrics. With this, we have created a few exciting products, like waterproof bags and cushion covers. We are now experimenting with handloom umbrellas. We also currently have 6 different fabric designs in two colourways, but we hope to expand this very soon.

Q COULD YOU SHARE WITH US ANY MEMORABLE EXPERIENCES OR STORIES WHEN BOTH OF YOU BEGAN PURSUING THIS CRAFT? I would say that all of our interactions with our artisans have been and are very special to us. We work with one family and we have created an amazing bond with them. We primarily collaborate with handloom weavers in Madampella. Latha and Bandula are 2 such handloom artisans who throughout the years, have been our teachers, guides, and sources of inspiration for Common Folk. Our fondest memory with them falls during the period when we were developing the Ombre handloom technique. After weeks of experimenting, we finally got to a point where the colours seamlessly blended and our efforts were finally rewarded. The excitement and happiness we felt at that moment was unexplainable. Sharing that with Latha and Bandula and watching the same reaction, when we first took our shoes to them, made it so much sweeter. Their happiness to see the result of our work has been the most gratifying feeling we have ever had as a brand.

Q DO YOU HAVE ANY ADVICE FOR SOMEONE INTERESTED IN PURSUING HANDLOOM TEXTILE WEAVING ? The only advice we can give as a start-up brand for anyone interested is to find your purpose. A shoe is a product, whether it is made from handloom or not. Our sneakers are special to us because they were just the beginning of something much more significant. Handlooms in our country have been a part of our heritage and culture for many years. At one point, we had a thriving industry with many factories and weaving mills. But in the past few decades,the industry has been reaching a state of inertia. We see many handloom sellers who produce an identical product range, often with the same aesthetics. This saturates the local market. So it is exciting to see a few inspirational local brands stepping out of the norm to create new designs and colour combinations to uplift the craft. At Common Folk, we believe our handloom sneakers are just a stepping stone for the industry in Sri Lanka to grow in streetwear culture and become enticing to the younger generations.

text Nuzla Rizkiya

0 Comments